YUTAKAJYUSHI CO., LTD.

YUTAKAJYUSHI CO., LTD.

- Plastic and rubber processing

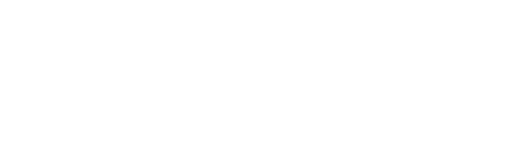

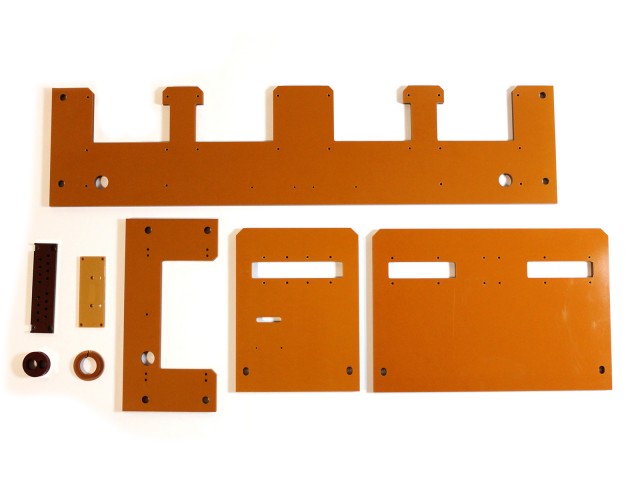

From general-purpose plastics to high-functional engineering plastics, we can handle all kinds of processing, ranging from single products and small quantities to mass production, as well as machining, assembly, welding, and bending.

Integrated production of die-stamping materials such as rubber, sponge, PET film, and more, from single or small quantities to mass production, machine parts, precision parts, covers, gaskets, etc., as well as various plastic processing and die-stamping for a wide variety of materials.

We utilize our location in Ota-ku, one of Japan's leading industrial areas, to respond to the diverse needs of our customers by taking advantage of our network of affiliated companies for processing services that we do not offer, such as resin molding, rubber molding, metal processing, painting, and silk printing.

Specialized Products, Technologies and Services

Plastic adhesion

We cut plastic sheets to the specified dimensions and perform solvent adhesion work to assemble products used for purposes such as safety covers, insulation covers, and cases for industrial equipment.

Plastic bending

We cut plastic sheets to the specified dimensions, apply heat to the bent portions, and then bend the sheets to produce products used for purposes such as safety covers and insulation covers for industrial equipment.

Die-stamping

We use Thomson molds to press thin materials such as plastic film, rubber, and sponge into various shapes including insulation sheets, cushions, and gaskets.

Current Status of Overseas Business

| On-site production | |

|---|---|

| Sales bases (incl. dealerships) | |

| Export | |

| Import | |

| Outsourcing production /processing | |

| Technology partnerships | |

| R&D bases | |

| Other |

Key Business Partners

Future Target Countries and Regions

Asia, Southeast Asia, North America, etc.

Overseas Business Prospects

Company Information

| Representative | Shigeki Oyama |

|---|---|

| Address | 3-15-2 Higashi Yaguchi, Ota-ku, Tokyo 146-0094 |

| URL | http://www.yutakajyushi.co.jp/ |

| Established in | 1970 |

| Capital | 10 million yen |

| Employees | 10 |

| International Certification (e.g. ISO) |

Contact

| Name | Shigeki Oyama |

|---|---|

| Position | Representative Director |

| Tel | +81-3-3731-1161 |

| Fax | +81-3-3733-8010 |

Ota City, Tokyo. Home of the excellent 4,200+ manufacturers

View Details Ota City Industrial Promotion Organization

Ota City Industrial Promotion Organization

Acrylic product adhesion, bending, cutting, and more

Acrylic product adhesion, bending, cutting, and more

PVC product adhesion, bending, cutting, and more

PVC product adhesion, bending, cutting, and more

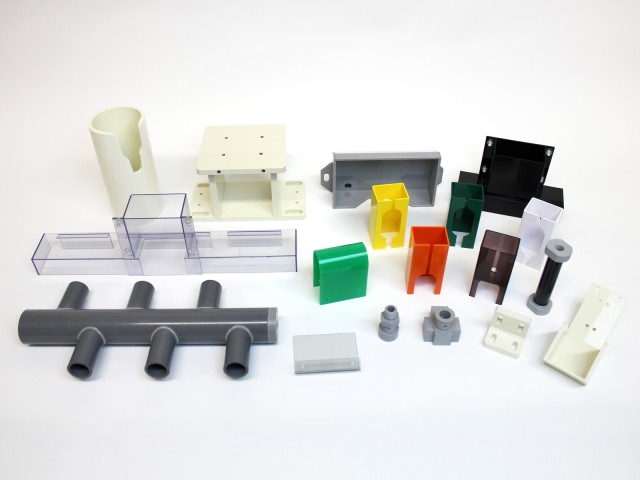

Phenolic resin parts mainly for insulation

Phenolic resin parts mainly for insulation

Engineer plastic product cutting

Engineer plastic product cutting

Die-stamping of film, rubber, sponge, and more

Die-stamping of film, rubber, sponge, and more

Various types of plastic sheet cutting

Various types of plastic sheet cutting